The testing process is a systematic way of assessing the performance of a seat part that is designed to pre-defined diverse field problems at a laboratory and optimizes the design of the seat part. HYUNDAI MSEAT owns 6 laboratories (sled laboratory included) and 93 types of testing equipment.

-

6-axle vibration test

A test designed to analyze a seat’s noise & vibration properties under actual vibration conditions

-

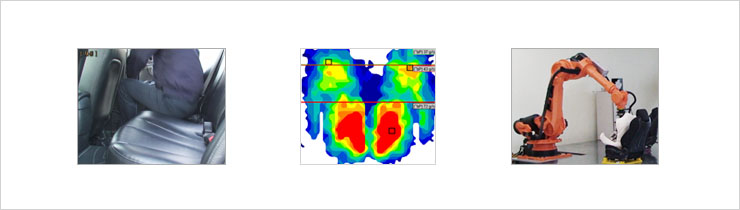

Durability test on robot-based lifting

A test designed to verify the durability of a seat covering under actual lifting (up & down) conditions

-

Noise & power-seat performance test

A test designed to verify the noise, performance & durability of a power seat

-

Static assessment test

A test designed to assess the firmness of a seat that can minimize injury to a passenger during a collision

-

Dynamic assessment test

A test designed to assess the firmness of a seat that can minimize any injury to a passenger (i.e. collision while driving a car, etc.)

-

Comfort test

HYUNDAI MSEAT has been able to maximize the comfort of automotive seating components through lab-based tests in static seating & dynamic driving properties.

-

Comfort assessment

HYUNDAI MSEAT has been able to maximize customer comfort through comfort assessments of seat through actual driving conditions and the customer clinics with local customers.